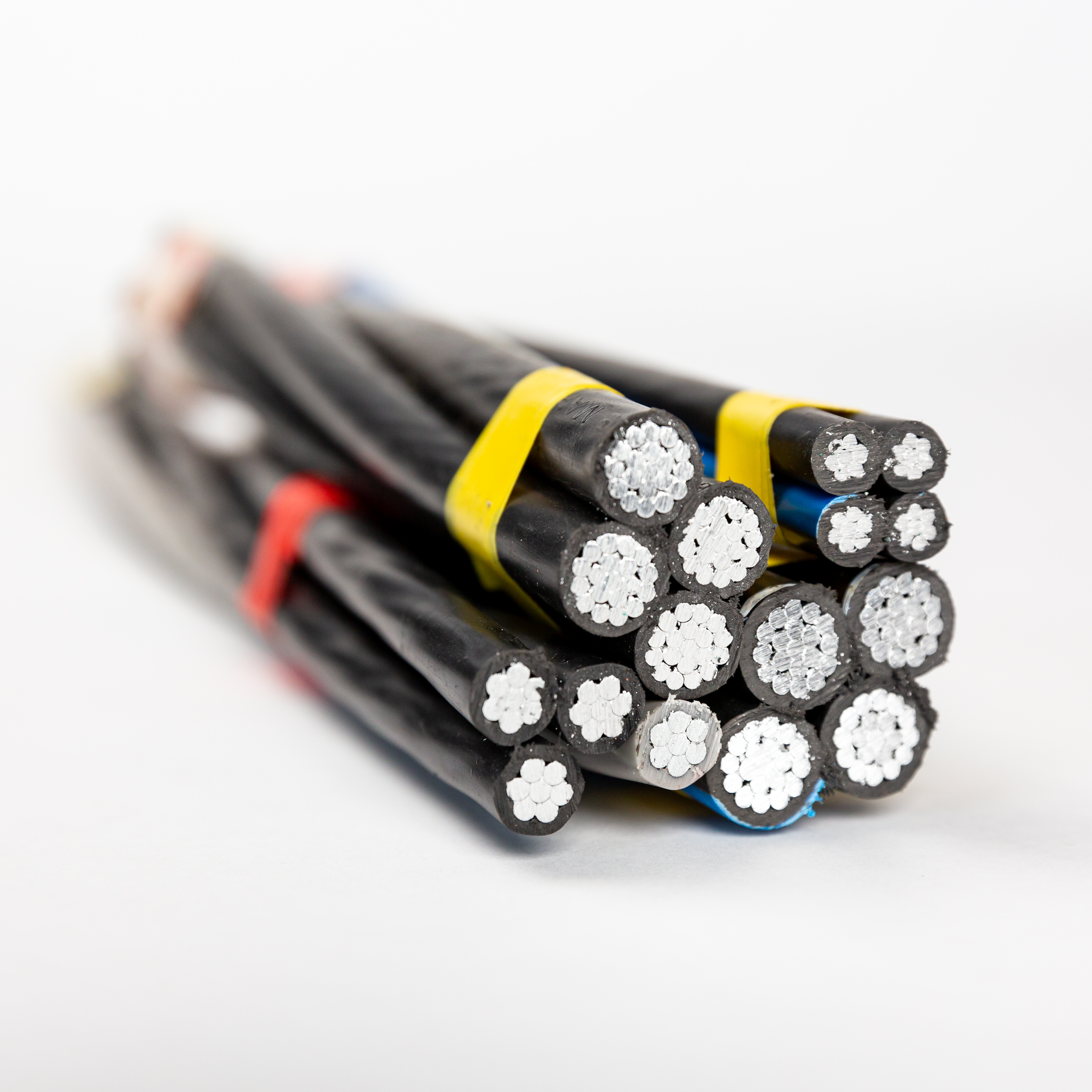

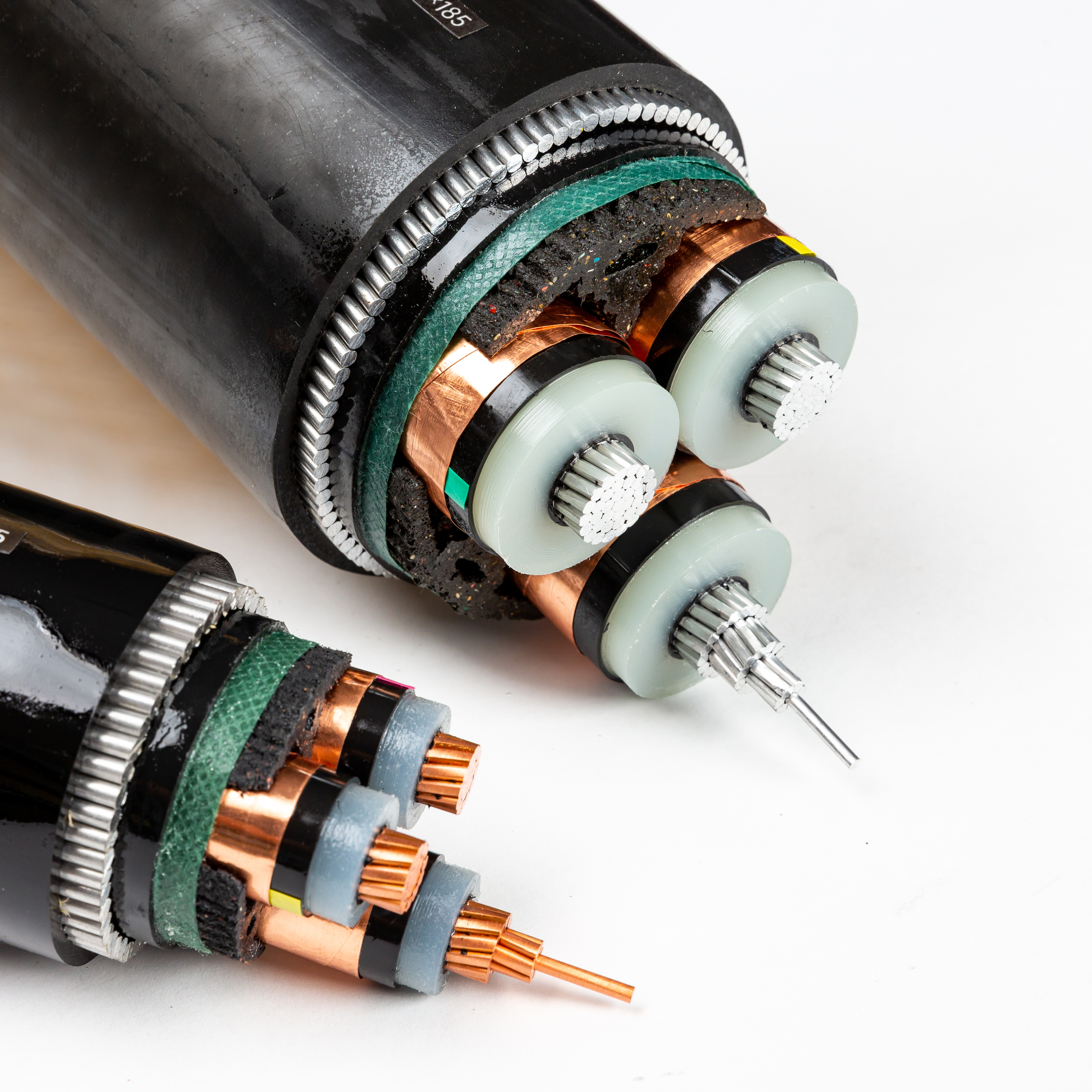

The main differences between standard cables and non-standard cables are as follows: (The pictures are of standard cables)

1. Material Usage

Standard Cables: High-quality, standard-compliant raw materials are used, such as copper or aluminum conductors, and qualified insulation and sheath materials.

Non-Standard Cables: To reduce costs, substandard or non-compliant raw materials may be used, such as lower purity copper wires, thinner or less durable insulation materials.

2. Safety and Reliability

Standard Cables: Due to the standardized design and testing procedures, they have high safety levels and stable electrical and mechanical performance, with a longer lifespan.

Non-Standard Cables: Since the materials and processes may not meet standards, they pose greater safety risks, have unstable electrical and mechanical performance, and are more prone to aging and short-circuiting. Their lifespan is usually shorter.

3. Price

Standard Cables: They are generally more expensive, but their quality and performance are guaranteed, meeting various electrical and construction codes.

Non-Standard Cables: These are usually cheaper, but the quality and safety are uncertain.

4. Application

Standard Cables: Widely used in fields like power distribution, communications, and construction, where strict quality assurance is required.

Non-Standard Cables: Primarily used in situations where the quality requirements are lower, the budget is limited, or there are special needs. However, they are generally not recommended for critical applications.

.jpg)